PLANNING AN INDUSTRIAL GAS DETECTION SYSTEM

There is a popular belief that when you install a gas detection system you make the installation safe.

This incorrect and dangerous statement cannot be made further from the truth.

An installation cannot be made safe by such a simple action; The safety of any installation begins at the design stage, good engineering and materials, and follows through construction to the development of safe operating practices undertaken by trained and competent personnel.

After the correct engineering and development of safe operative practices only then can gas detection accept a role to assist and improve the overall safety of the installation.

A fixed gas detection system has one prime role, that of a safety device.

In the normal operation of a process the gas detection system should never be activated, its initial task is that of a 24 hour ’sentinel’, monitoring chosen atmospheres looking for the occurrence of an abnormal event which could indicate the failure of a plant item or an incorrect and potentially hazardous operating practice.

Under such circumstances, the second task is for the gas detection system to provide a rapid response to be abnormal event, so that remedial action can be taken before the developing gas or vapour cloud can become of a size that a catastrophe becomes a possible result.

A gas detection system of the type envisaged for an installation should be never used to monitor of a process or procedure, which is the role of a process analyser.

In the event of a gas detector being used to monitor a process, there is a very real risk that operating personnel will grow accustomed to a regular activation of gas detection system due to ‘normal’ operations.

Under such circumstances there is a very real danger that the occurrence of an abnormal and hazardous event will pass unnoticed and not differentiated from a ‘normal’ operation.

Gas Detection System Size:

There is no ‘correct’ size for a gas detection system.

It is clear that the larger the system becomes for a fixed site volume, the greater is the probability of detecting a small toxic or flammable gas cloud and that the time taken to detect will similarly reduce as the system size increases.

This logic however, excludes both the capital cost of such a system and its ongoing cost of ownership.

A compromise therefore becomes necessary between the benefit of a system and its cost.

This compromise is by definition subjective; it can be based on many factors example:

A sum of money within a budget

A philosophy, such as perimeter monitoring at, say, 20 metre intervals

Mathematical predictive modelling to assess the time to respond to known events and providing a gas detection system to be faster in response than the required time to respond.

Personal opinions of experienced plant personnel.

The analysis of the perceived hazard on an area by area basis.

In reality, the final decision as to system size is usually combination of these factors.

Deciding What’s ‘Essential’

Whilst is an ideal world we would aim to detect gas leaks, from financial and engineering constraints fixed sensors are usually placed so as to detect gas accumulations which could create a ‘Significant Hazard’.

At this stage therefore, we need to define what is a ‘Significant Hazard’? Whilst there will be many different views, one definition could be an event where people would get hurt and plant/buildings get damaged.

Within the oil and gas industry there is some support for defining this as the energy released when a 5 metre diameter gas cloud containing a stoichiometric gas mixture ignites approximately 10% natural gas in air for a high methane based natural gas.

Remember you only need an overpressure of approximately 150 millibars within a normal building to damage the structure.

Following this regime, one would be required to place a gas sensor in a horizontal 4 metre triangular matrix in ‘Special Hazard’ areas.

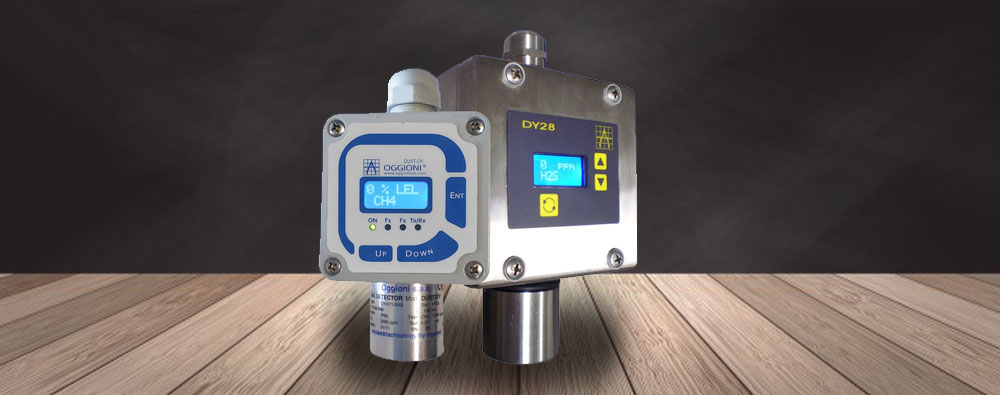

In addition to the flammable hazard of the many different hydrocarbons processed within a complex, there is also invariably the toxic hazard of hydrogen sulphide and in my opinion, when the volumetric concentration of hydrogen sulphide in high pressure gas system is greater than 500 ppm H2S then the area becomes a hazard from toxic gas viewpoint.